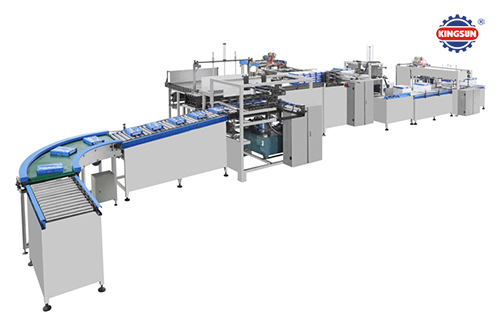

KCP-A4-10 Model A4 Copy Paper Cutting & Packaging Machine is the best choice for the small middle capacity production or for the new start paper converting company. The machine with world advance level technology and international brand electric components, makes its most reliable and stable paper converting machine for A4 or A3 cut size copy paper. The unwinding with two rolls paper cutting together. It is compact design to save space and easy for operation.

KCP-A4-10 Model A4 Copy Paper Cutting & Packaging Machine is the best choice for the small medium capacity production or for the new start company.

The machine with world advance level technology and international brand components, makes its most reliable and stable paper converting machine for

A4 or A3 cut size copy paper. With features of low investment budget, easy for operation and less labor power, so it is one of most suitable equipment for making

A4, A3 paper.

Main Features:

1) Air cylinder type unwind system is adopted to pick up the paper reels. Magnetic Power Brake is adopted to control the tension, keeping the machine run smoothly.

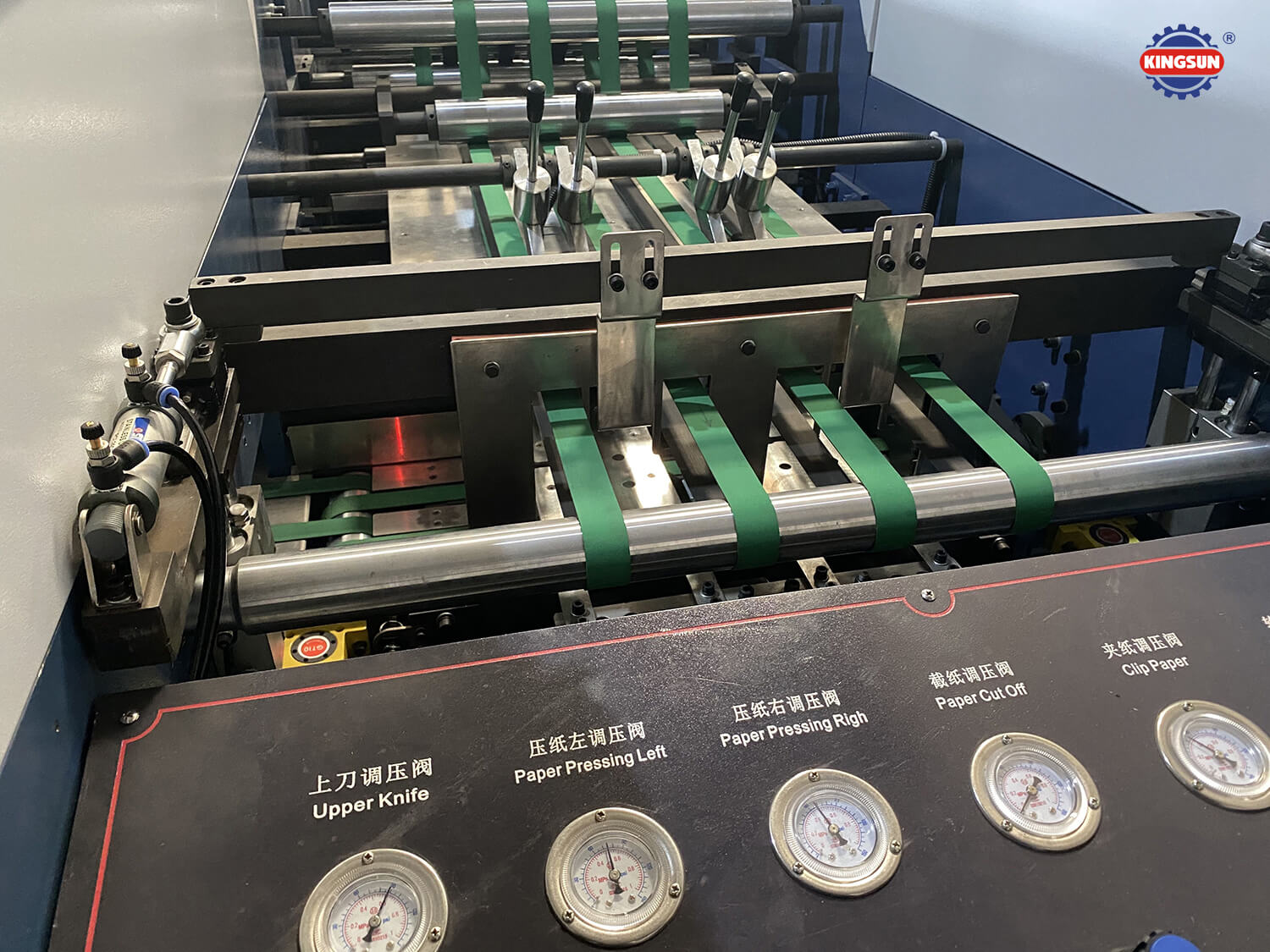

2) Slitting Blade is made in German, featured by accurate positioning, easy adjustment, long service life and less grinding.

3) Cross Sheeting blade is made in German, TCT. Synchronic type, shear cutting method.

4) Conveying belt is from Switzerland Rapplon. Timing Belt is from German Continental

5) The German vibration motor is adopted, with low noise.

6) Electric components of SIMENS,OMRON,SCHNEIDER,YASKAWA are adopted, keep smooth running for long life machine.

7) High speed: max.250-300m/min

8) High production capacity:5-6 reams/min

9) Small space required: 8m x 8m

10) Easy operation and maintenance.

11) Less labor power: only 3 operators required

12) Low investment budget for production equipment

Main technical specifications:

Sheet Cutting Unit:

| Shaftless Unwinding Reels | 2 |

| Number of Slitting knife | 5 |

| Min. Width of Paper Roll(mm) | 846 |

| Net Cutting Width(mm) | 840 |

| Diameter of Paper Roll(mm) | 400-1200 |

| Diameter of Core Chuck(mm) | 3”(76.2mm) or 6”(152.4mm) |

| Paper GSM(gsm) | 60-100 |

| Length of Sheet Paper (mm) | 297 |

| Paper Quantity per Ream (pcs) | 0-500 |

| Max. Ream Height(mm) | 65 |

| Max. Designing Speed (m/min) | 200-250 |

| Cutting Speed(times/min) | 850 |

| Frequency of Ream Discharge (times/min) | 5-6 reams |

| Working Speed of Paper Running(m/min)) | 250-300 |

| Working Cutting Speed (times/min) | 1010 |

| Output speed(pack/min) | 10-12 packs |

| Max. Knife Loading(gsm) | 400 |

| Paper Cutting Accuracy(mm) | ±0.2 |

| Requirement for Paper Reel | 1.Paper running speed stable; 2. Paper roll no broken connection; 3. Qualified paper. |

| Transmission | AC converter control,stepless speed regulation |

| Main power | 380V/50Hz 3 phases 4 lines |

| Control voltage | 220V AC/22V DC |

| Total power(KW) | 12 |

| Air Consumption (NL/min) | 300 |

| Pneumatic Pressure(bar) | 0.6-0.8 |

| Overall Dimension(m) (L x W x H) M | 7.8 x 6.6 x 1.8 |

| Weight (Tons) | 12 |

Packaging unit:

|

Packing Speed (reams/min) |

10-12 packs |

|

Cover Paper Automatic Transverse Cutting and Feeding |

10-12 pieces |

|

Specification of Packed Object (mm)(based on height 500 pcs of copy paper) |

210×297×50 |

|

Power Supply |

380V 50HZ 3 phase, 4 lines or special made |

|

Motor Power(KW) |

5.1 |

|

Gluing Power(KW) |

2.25 |

|

Compressed Air(Mpa) |

0.6-0.8 |

|

Overwrapping Paper Size(mm) (LW) |

550-560 X 386 |

|

Overall Dimension(mm) (L x W x H) |

3400 X 3300 X 1600 |

|

Weight (Tons) |

1.5 |

Please write more details of your specific requirement, so our sales team can provide you right machine you need.

kingsungroup

kingsungroup E-mail Us

E-mail Us

PDF Download

PDF Download Video Link

Video Link