This machine is composed by feeder,printer,slotter,die cutter,stacker five components.

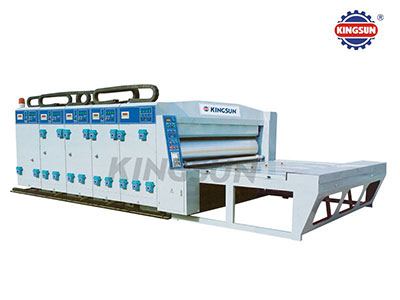

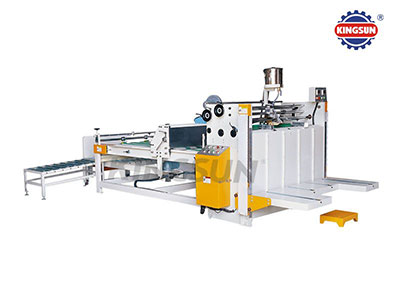

High speed flexo printer slotters and in line die-cutter machines

Functions and features:

1.This machine is composed by feeder,printer,slotter,die cutter,stacker five components.

2. Feeder has lead edge feeder or kick feeder.

3.Equipped with high-pressure vacuuming device,can sweep off scraps of paper and impurities on the printing face of cardboard

4.Transmission gear use good quality alloy steel,after carburizing and quenching,use spray lubrication and oil way balance system.

5.Use spray lubrication and oil line balanced system.

6.Use PLC touch screen multifunction controller.Host machine,fan,phase motor and so on are using frequency conversion control.

7.Slotting unit is electric adjusting each part sizes of the carton box.

8.Stacker unit front pneumatic go up and down,back photoelectric tracking,auto going up.

Main technical parameter:

|

Parameter name |

Unit |

Size |

|||||

|

ZYK1270*2100 |

ZYK1270*2500 |

ZYK1270*2800 |

ZYK1570*2500 |

ZYK1570*2800 |

|||

|

Economic speed |

pieces/min |

110 |

100 |

||||

|

Max.feeding size |

mm |

1270*2200 |

1270*2600 |

1270*2900 |

1500*2600 |

1500*2900 |

|

|

Min.feeding size |

mm |

350*650 |

400*700 |

||||

|

Skip feeding |

mm |

1500*2200 |

1500*2600 |

1500*2900 |

1650*2600 |

1650*2900 |

|

|

Max.printing size |

mm |

1200*1200 |

1200*2500 |

1200*2800 |

1500*2500 |

1500*2800 |

|

|

Color accuracy |

mm |

double-color*0.35 three-color±0.5 four-color±0.75 |

|||||

|

Standard printing plate thickness |

mm |

7.2 |

|||||

|

Min.slotting distance |

mm |

290*60*290*60 |

|||||

|

Max.slotting depth |

mm |

300 |

220 |

||||

|

Printing roller axial adjustment |

mm |

±7 |

|||||

|

Fitting die cutting cardboard thickness |

|

3-5ply(slotting fitting cardboard thickness 3,5,7 Ply) |

|||||

Please write more details of your specific requirement, so our sales team can provide you right machine you need.

kingsungroup

kingsungroup E-mail Us

E-mail Us

PDF Download

PDF Download Video Link

Video Link