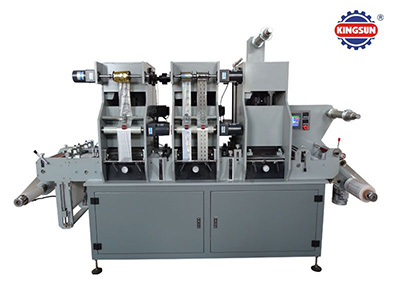

The double station label die cutting machine designed to add one extra station hot stamping unit onto the basis of the standard single station label die cutting machine, which can realize the hot stamping and die-cutting at one processing, and can also complete two times die-cutting work.

Double station label die cutting machine, label hot stamping machine, hologram label hot stamping machine

This two station label die cutting machine is mainly for hot stamping and die cutting together at one process, so can save time and improve efficiency. Economic cost and high speed, so it is an ideal equipment for the high grade label converting.

Characters:

1. The machine is to add one hot stamping station on the basis of the standard single station label die cutting machine, which can realize the hot stamping and die-cutting in one time, and can also complete two times die-cutting work.

2. The machine is flat-pressed and high-precision die-cutting. The material and the slicing are controlled by the servo controller.

3. The two sides of the printing mark and the longitudinal color mark are accurately tracked and positioned by three photoelectric eyes. The machine complete the roll of die cutting, hot stamping, waste rewinding, sheeting at one time and fit for automatic labeling machine.

4. It is very suitable for die-cutting of paper self-adhesive labels, polyester film labels and laser anti-counterfeiting labels.

5. This machine is the best auxiliary equipment for high-speed reel label printing machine, flexographic printing machine, continuous screen printing machine, gravure printing machine and anti-counterfeiting label embossing machine. It is the most ideal and efficient model for all label making factories. It is also suitable for die cutting in the electronics industry and adhesive tape products industry.

Main specifications:

|

Model |

KTM-320D |

|

Die Cutting Speed |

20-200 times/min |

|

Max. Web Width |

320mm |

|

Max. Die Cutting Width |

310mm |

|

Max. Die Cutting Length |

300mm |

|

Max. Feeding Diameter |

600mm |

|

Positioning Precision |

+/-0.1mm |

|

Main Motor Power |

5.5KW |

|

Machine Weight |

2600kgs |

|

Dimensions (L x W x H) |

3700 x 1200 x 1600mm |

Please write more details of your specific requirement, so our sales team can provide you right machine you need.

kingsungroup

kingsungroup E-mail Us

E-mail Us

PDF Download

PDF Download Video Link

Video Link