1. Able to do single or double side lamination.

2. With oil- free vacuum pump for automatic paper feeding.

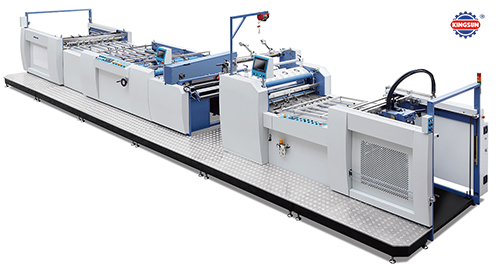

Features:

1. Able to do single or double side lamination.

2. With oil- free vacuum pump for automatic paper feeding.

3. Automatic paper feeding system equipped with photocell detector and machine automatic stops to self- protection while short of paper or paper breaks.

4. Man- machine interface system: color touch screen, easy for operation; it realizes automatic operation after directly data input for paper size, overlap length and working speed, working status can be tracked via the screen.

5. Schneider frequency converter, speed variable

6. The upper & the lower heating rollers with casted aluminum heater, independent temperature control, which ensures the temperature constantly and makes it precise for the double lamination.

7. Pneumatic pressure system ensures a stable pressure; it can be adjusted upon requests.

8. The anti-curve device can be adjusted by the turbine gearbox, the laminated paper can be leveled and it does not curve after cutting.

9. Pneumatic sheet cutting system able to have sheet laminated paper

10. The receiving table equipped for the sheet laminated paper

Main specifications:

|

Model |

KFM-540B |

|

Max. paper size |

540 x 780mm |

|

Min. paper size |

290 x 290mm |

|

Working speed |

30m/min (single); 25m/min (double) |

|

Paper thickness |

100-500g/m2 |

|

Total power |

18kw |

|

Dimensions |

3200 x 1250 x 1500mm |

|

Weight |

1.3T |

Please write more details of your specific requirement, so our sales team can provide you right machine you need.

kingsungroup

kingsungroup E-mail Us

E-mail Us

PDF Download

PDF Download Video Link

Video Link