Holographic Film Making Machines for Hologram Film Production

What is hologram technology?

Hologram technology is a type of imaging that creates three-dimensional representations of objects or scenes using light diffraction, interference, and recording. It involves the use of laser beams to create a holographic image of an object or scene by splitting a beam of light into two parts- one part that illuminates the object and another that is used as a reference beam. These beams are recorded on a photographic plate or a holographic film to create a 3D image that can be viewed from different angles.

What is holographic film?

Holographic film is a thin plastic material that displays a three-dimensional image, known as a hologram. It is created using a photographic technique that records the interference pattern of light waves generated by an object or scene. When viewed under proper lighting conditions, the hologram appears or depicted in the image are actually present.

What are applications of holographic films?

- Security: Holographic films can be used for security purposes, such as in banknotes or passports, to protect against counterfeiting.

- Packaging: Holographic films can be used for packaging to create a stunning visual effect, making the package more enticing and eye-catching.

- Branding: Holographic films can be used to create unique branding for a product or company, making it stand out from competitors.

- Advertising: Holographic films can be used in advertising to create attention-grabbing displays.

- Education: Holographic films can be used in education to create interactive displays and visual aids, making learning more engaging.

- Entertainment: holographic films can be used in entertainment, such as in holographic concerts or augmented reality experiences.

- Medical: Holographic films can be used in medical imaging, creating three-dimensional representations of medical images for better visualization and analysis.

What can we get from the holographic film making machine?

- Improved visual effects: Holographic film machines produce highly realistic and vivid 3D images that offer an immersive experience for viewers.

- Versatility: The technology can be applied across different industries, including entertainment, advertising, security, and art. This versatility means more opportunities for businesses and individuals to make use of the technology.

- Cost-effective: Holographic film machines can be used to create cheaper holographic displays, which can be displayed in multiple locations, thus making them more cost-effective than traditional holographic displays.

- High-resolution images: The technology produces high-resolution images that are both dynamic and sharp, making them perfect for use in high-visibility areas and for presentations.

- Easy to use: Holographic film machines are easy to use and do not require any special technical skills, making them easily accessible to a wide range of users and businesses.

- Enhanced security: Holographic film machines can help to improve security by creating highly realistic and difficult-to-replicate security features, such as holographic IDs, licenses, and other important documents.

- Reduced environmental impact: The technology uses less material than traditional printing methods, which reduces the environmental impact of creating visual displays.

What holographic film making machines do we need to produce these holographic films?

We Kingsun Machinery offer complete sets of holographic film making equipment, from very beginning of master plate making to the finished holographic film, we provide for you the full holographic technology, all necessary technical support, such as installation commissioning and training for the customers, and solution formular for the equipment, so that the customers can fully understand the equipment and well handle it during the operation.

Depending on your actual situation, you can get it started from all these full sets of equipment or you can select it one or two of them to add it to your current production line, or to save cost for a new starter you can start it with the electroforming machine and embossing machine, in that case we will make the master for you and you can duplicate the working shim from the electroforming machine then, so that you can have your hologram sticker business faster and bring the benefits for you quicker then.

Full sets equipment to make holographic film:

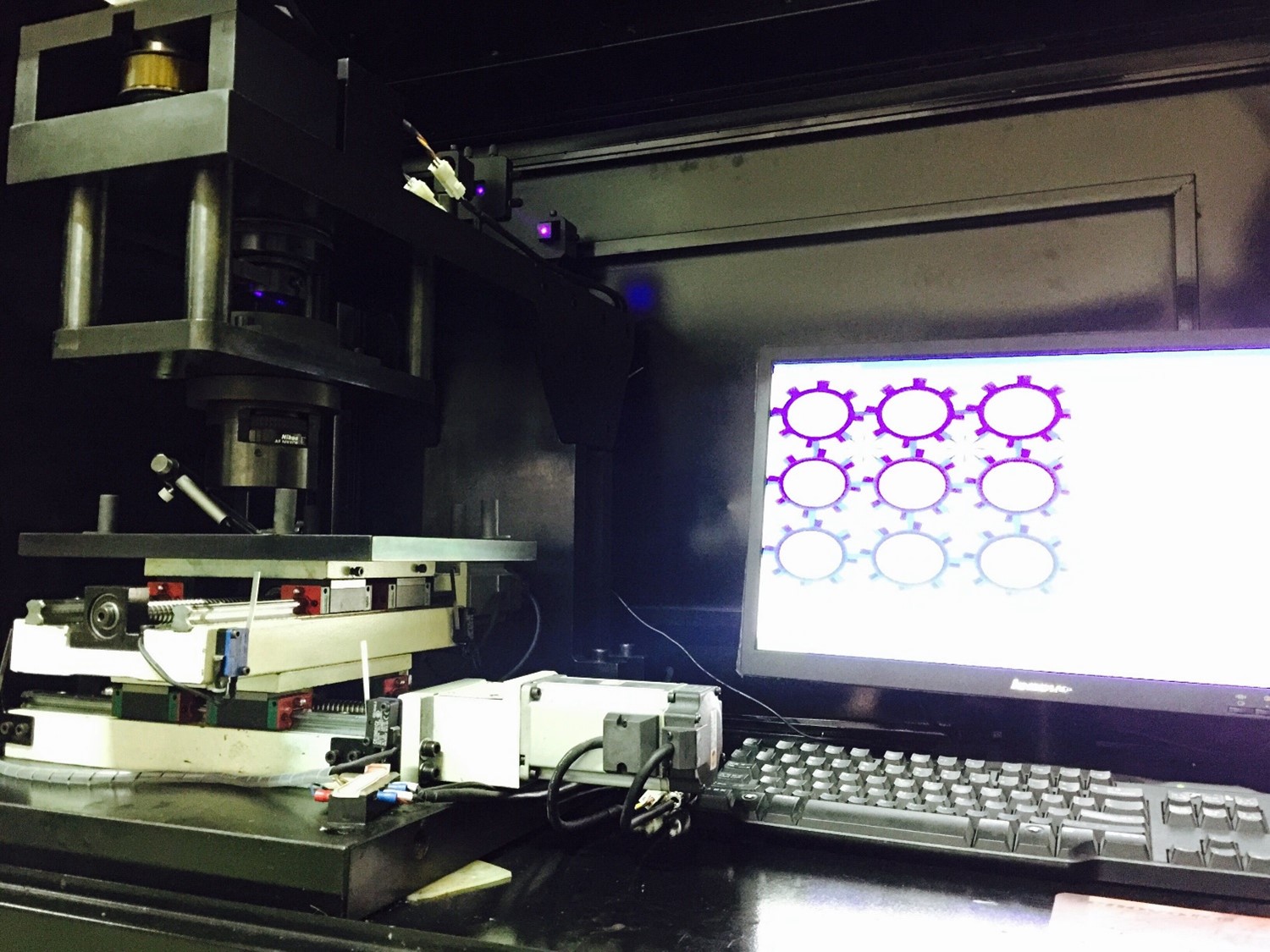

1. Laser holographic dot-matrix machine

2. Electroforming machine

3. Recombination machine

4. Holographic embossing machine

Kindly find more details as below:

1.Laser holographic dot-matrix machine, equipment to make the master plate by using a laser beam to create holographic images and texts in a dot-matrix pattern. The laser beam is directed onto the film or plate, creating a series of dots that form a holographic image. These dots are arranged in a dot-matrix pattern for precision and accuracy. The result is a visually striking and secure image that can be used for a range of purposes.

This digital laser holographic lithography plate-making system is an intelligent design and production system, with dynamic image processing and control system. The letter and image can be designed in dynamic lattice image, which shaped into round, square, diamond, multi-layer or curve and to be made as the original master, the laser image is dynamic in any viewing angle under any light.

2.Electroforming machine, equipment to duplicate the working shim from the master plate. There is an electroforming tank that is filled with an electrolyte solution, and an anode is placed in the solution. When an electric current is passed through the solution, metal ions are transferred from the anode to the substrate, this electroforming process will form the master original shim or small sized hologram nickel shim for recombination.

This electroforming machine is essential equipment to produce holographic laser stickers, with high fidelity and high duplication ability, ensuring the high-quality working plate & master plate for the next step of the recombination and die cutting, with high frequency DC input.

This electroforming machine consists of electroforming tank for the electro-deposition of the nickel and the controller, able to conduct the electric current, when the deposition is finished, it can separate the newly duplicated nickel hologram working shim from the nickel master plate.

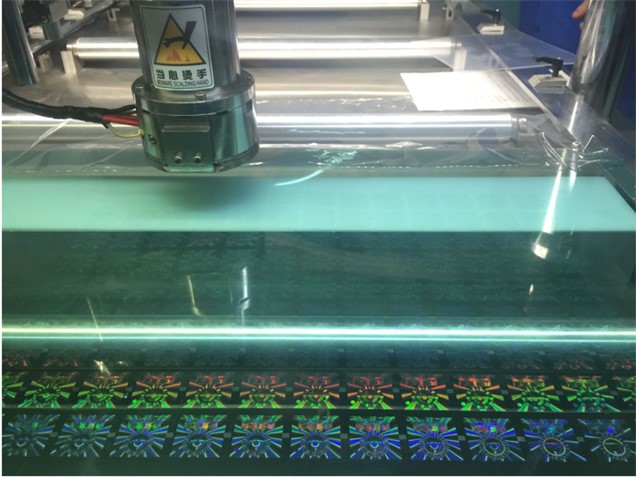

3. Recombination machine, equipment to recombine the master into a broad width size. This recombination machine to fix the small pieced hologram nickel onto the die mold head, and press it onto the PC sheet to get big sized plastic holographic master, after this recombination, we get a bigger sized PC sheet with 2D/3D hologram effect onto it and we go back to electroforming machine to get a big sized original holographic master.

This compact recombination machine is PLC automatic controlled, ensuring the positioning, derangement, inclination, spacing can be automatically and precisely arrange; precision up to 0.01mm, ensuring there is no seam on the plate; able to achieve the best effect of the plate; this compact recombination machine is easy for operation, high precise recombination, with a stable and reliable performance; equipped with anti-static dust removal, realizing a neat and clear surface of the plate.

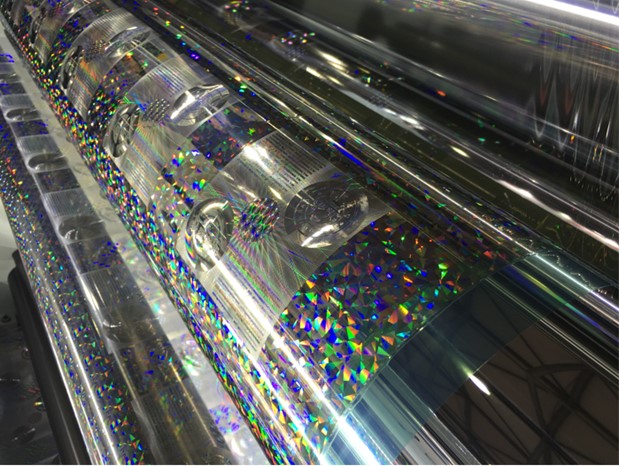

4. Holographic embossing machine, equipment to create the holographic effect on the film BOPP, PVC, PET, CPP, aimed to produce the holographic laser film, transfer film and packaging film that widely applied in tobacco & alcohol packages, the food packages and the other fields. It works as to make different design maters first, then by using of working plates to emboss on all kinds of films, which resulted in a dazzling rainbow laser holographic film. It is a new type of special equipment for anti-counterfeit and practical decoration emerging materials.