JBZ-S12 double-side PE coated automatic paper cup forming machine is a multi-station full-automatic machine for producing double-sided PE coated drink cups, ice cream cups or conical vessels of other food containers through continuous process of paper feed

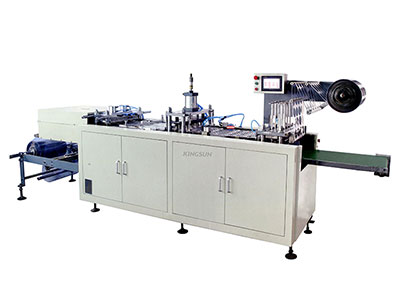

JBZ-S12 double-side PE coated automatic paper cup forming machine

JBZ-S12 double-side PE coated automatic paper cup forming machine is a multi-station full-automatic machine for producing double-sided PE coated drink cups, ice cream cups or conical vessels of other food containers through continuous process of paper feed, ultrasonic medium welding, tube forming, cup rabbet lubrication, oil injection, bottom flushing, duplex bottom heating, bottom knurling, upper mouth hemming and finished product stacking. Because of ultrasonic seal technology, the product is suitable for double-sided PE coated paper and full printed drink cups, ice cream cups and other conical vessels.

Main technical specifications:

|

Model |

JBZ-S12 |

JBZ-S16 |

JBZ-S22 |

|

Size of cup |

6oz,8oz,12oz |

12oz,14oz,16oz |

16oz, 22oz |

|

Paper material |

Single-sided, double-sided PE coated paper |

||

|

Outer diameter of cup rabbet |

50-95 |

50-95 |

50-95 |

|

Outer diameter of cup bottom |

35-70 |

35-70 |

35-70 |

|

Cup height |

50-120 |

100-150 |

100-175 |

|

Bottom depth |

≤10 |

≤10 |

≤12 |

|

Conicity |

2-8° |

2-8° |

2-8° |

|

Rated productivity |

40-50pcs/min |

35-45pcs/min |

30-40pcs/min |

|

Power supply |

380V 50Hz |

||

|

Total power |

6.5KW |

8KW |

|

|

Weight |

1600Kg |

1700Kg |

1900Kg |

|

Packing (LX W XH) |

280×135×180cm 80×75×130cm |

300×145×190cm 80×75×135cm |

330×145×200cm 80×75×135cm |

|

Air Pressure |

0.2m3/min;0.6MPa (provided by customer) |

||

Please write more details of your specific requirement, so our sales team can provide you right machine you need.

kingsungroup

kingsungroup E-mail Us

E-mail Us

PDF Download

PDF Download Video Link

Video Link